Presenting a state-of-the-art inventory racking system

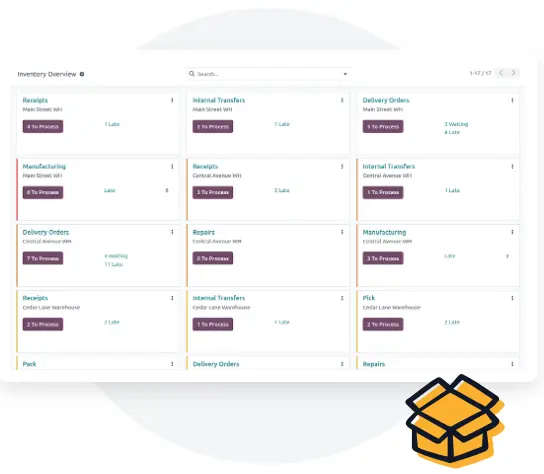

Wera Inventory powered by Odoo, Enhance inventory control, streamline operations, optimize delivery routes, and gain real-time visibility with Wera's cutting-edge warehouse management application.

Optimize the speed of receipt handling, quality assurance, and storage procedures

Manage inbound and outbound shipments effectively through the enforcement of push and pull regulations, adherence to GS-1 coding standards, and the implementation of customized routing protocols.

Optimize storage operations by employing strategic put-away techniques such as categorizing items based on their movement speed, conducting ABC analysis, and utilizing cross-docking methods to minimize part transfers and reduce overall travel distances.=

Impeccable restocking

Prevent stockouts by employing sophisticated replenishment tactics like min-max rules, Make-to-Order (MTO), or the master production schedule. Utilize Wera's capabilities to suggest or automatically initiate purchase orders. Enhance vendor relations by automating follow-ups for PO acknowledgment, confirming receipt schedules proactively, and other communication tasks.

Optimize your warehouse

Cutting-edge inventory control system offering a full suite of functionalities including serial numbers, lots, packaging, reservation strategies, cycle counting, KPIs, and more...

Speedy barcode scanner

Quickly access all expenses, reports, and statuses on the dashboard.

Stock assessment

Wera provides robust support for multiple valuation methods such as FIFO, Average Price, LIFO, and Standard Price, catering to both perpetual and periodical inventory management needs.

Enhance efficiency by choosing optimal routes

Streamline procurement processes by meticulously charting complex routes in Wera and automating the planning of transfers.

Exercise precise control over supply chain operations through strategic coordination of actions across multiple applications.

Enhanced traceability

Real-time monitoring of stock, inventory transactions, and production activities.

Discover all the features

First list of Features

Inventory: For Hospitality (Hotels, Restaurants, QSR etc.), Retail stores, Service based business, Agriculture, Education & training, Financial services , E-commerce